RevOps for Manufacturing: Integrating Sales, Marketing, and Service for Sustainable Growth

So, you've stumbled into the world of RevOps, and you're wondering how this jazzy term fits into the nuts and bolts of manufacturing? Let's dive into the not-so-secret sauce that could turbocharge your factory floor to the front office. Buckle up; it's going to be a ride full of insights and maybe a couple of corny jokes. 😄

What's RevOps, Anyway?

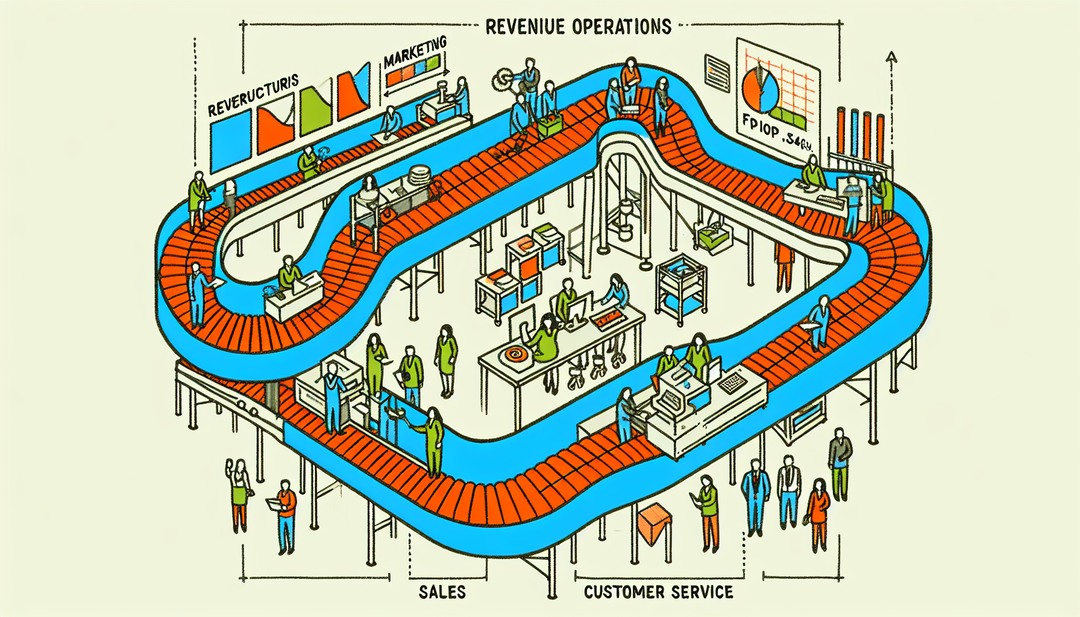

Imagine a world where sales, marketing, and customer service are not just playing nice but actually rowing the boat in the same direction. That, my friend, is the utopia RevOps promises. Revenue Operations (RevOps) is about breaking down the silos and getting everyone on the same page to drive growth. It's like having a supercharged engine where every part works in perfect harmony. Sounds dreamy, right?

The Manufacturing Twist

Now, when it comes to manufacturing, things can get a bit... well, complex. You've got supply chains that are more tangled than your last attempt at holiday lights, production schedules tighter than a new pair of shoes, and customer demands that change faster than weather in April. How does RevOps fit into this whirlwind?

The Assembly Line of Success

Here's how RevOps can rev up the manufacturing game:

- Unified Data: Imagine having a crystal ball that shows you exactly what's happening across your business. RevOps builds this by integrating data across sales, marketing, and customer service. This means you can predict demand, streamline production, and keep your customers happier than ever. Magic? No, it's RevOps!

- Silos, Be Gone: In many manufacturing companies, departments can be as isolated as desert islands. RevOps builds bridges (or, let's say, constructs sturdy conveyor belts) to connect these islands. This means your team can collaborate more effectively, reducing bottlenecks and accelerating growth.

- Customer-Centricity: At the heart of RevOps is a laser focus on the customer. For manufacturers, this means not just meeting but anticipating customer needs. Custom orders? No problem. Faster delivery? Consider it done. By aligning your teams around the customer, RevOps helps you deliver a standout experience.

From Theory to Factory Floor

So, how do you bring RevOps to life in a manufacturing setting? Start small. Pick a project where sales, marketing, and customer service overlap, and focus on aligning these teams. Use shared data to make decisions, and celebrate the wins together. Before you know it, you'll see the RevOps magic happening.

Streamlining Customer Feedback Loops

A great starting point is to create a system where customer feedback is not just heard but acted upon—fast. This involves setting up a seamless flow of information from customer service to product development and sales. Imagine customer service flags a recurring issue with a product. With RevOps, this feedback quickly informs production adjustments and sales strategies, ensuring the issue is resolved and communicated effectively, minimizing customer dissatisfaction and boosting trust.

Optimizing Inventory Management with Predictive Analytics

Manufacturers often struggle with the delicate balance of inventory: too much and you're wasting resources, too little and you can't meet demand. A RevOps project could focus on integrating sales forecasts, marketing campaigns, and production schedules into a unified predictive analytics model. This model would not only forecast demand more accurately but also suggest optimal production levels and inventory management strategies, reducing waste and increasing responsiveness to market changes.

Enhancing Cross-Departmental Product Launches

New product launches are crucial moments for manufacturers, requiring tight coordination across several departments. A RevOps project here would establish a framework for these cross-functional teams, ensuring marketing campaigns align with production capabilities and sales teams are ready to hit the ground running. By using shared data and regular cross-departmental meetings, the launch process becomes smoother, market response times quicker, and the overall impact of new products is maximized.

Each of these projects not only exemplifies RevOps in action but also addresses key challenges in the manufacturing industry, leading to improved efficiency, customer satisfaction, and ultimately, revenue growth.

The Takeaway

RevOps might sound like the latest buzzword on the block, but for manufacturers willing to take the plunge, it can be a game-changer. By fostering collaboration, leveraging data, and keeping the customer at the center, RevOps can help manufacturers streamline operations, boost sales, and enhance the customer experience. And who wouldn't want that?

Alright, that's a wrap! Hope you found this dive into RevOps for manufacturers as enlightening as finding that last screw you needed to assemble your IKEA furniture. And if you need help with RevOps assembly I'm an open book (a time here).